How water treatment makes our water safe to drink and protects waterways

At night, you sleep, maybe getting up to go to the bathroom once or twice. In the morning, you take a shower, brush your teeth to the sound of running water from the tap and make coffee. This daily rhythm of life is unremarkable unless you’re in the water treatment business, where it is known as “diurnal flow.” At the J.D. Phillips wastewater treatment plant in north Colorado Springs, the amount of discharge coming into the plant on a weekday morning can rise 600 percent within a few hours, which is where “water management” comes into play, says the plant’s superintendent William Hoyt.

Water management at the plant Hoyt oversees means choosing an appropriate number and size of detention tanks for incoming wastewater to go through first stage treatment. During the detention period, heavier solids settle to the bottom while oil, grease and lighter solids float to the surface. The number of tanks in use must be averaged to maintain treatment levels at both peak and off-peak hours. If the tanks fill too slowly, leaving some of the wastewater in the tank for a longer period, they can become putrefied or “septic.”

To most of us, our public water systems— drinking water, wastewater and stormwater— are out of sight and out of mind. What the systems do for Colorado cities and towns, however, is vital, and those systems require vigilance, knowledge and ingenuity to ensure domestic water is safe to drink and that wastewater and stormwater don’t pose a threat to the environment.

Only in the past 100 to 150 years have scientists determined the importance of safe drinking water. For most of human history, cities have been spawning grounds for disease, dependent on migration from the outside to replenish their populations.

In the United States, the introduction of water filtration and chlorination in major cities between 1900 and 1940 accounted for approximately a 15 percent decline in urban death rates, according to research published in the journal Demography. Before the introduction of filtration and chlorination, city residents died at rates 30 percent higher than rural residents. In the late 1800s, infant mortality was 140 percent higher in cities than in the countryside.

Drinking Water Treatment

In the 1970s, a rising public awareness of environmental issues, discovery of chemical and organic contamination in public drinking water, and the lack of enforceable, national standards led to the passage of several federal environmental laws, including the Safe Drinking Water Act of 1974. That law, administered by the U.S. Environmental Protection Agency and its partners, is the cornerstone of modern drinking water treatment.

The Safe Drinking Water Act gave the EPA authority to delegate the primary responsibility for enforcing drinking water regulations to states. Here, the Colorado Department of Public Health and Environment (CDPHE) adopts, implements and enforces the standards set by the federal drinking water program. The state agency has further delegated enforcement of standards for private wells and campgrounds to county health departments.

Drinking water treatment plants use a series of processes involving physical, chemical and biological changes to remove suspended material and turn raw water into drinking water. Chlorine is typically used as a disinfectant, added either before the water enters the treatment process or just before it moves into the distribution system. In some Colorado systems such as the city of Thornton, a burgeoning Denver suburb, state-of-the-art technologies are appearing to replace or augment steps in the procedure. At Thornton’s renovated Wes Brown Water Treatment Plant, ultra-filtration (UF) membranes remove suspended solids in the source water, and ultraviolet (UV) disinfection

technologies take the place of chlorine to remove pathogens.

Pathogenic microbes are the contaminants of biggest concern for water treatment systems, according to Denver Water spokeswoman Stacy Chesney. These include bacteria, viruses, giardia and cryptosporidium, which can cause a range of acute sicknesses or even death from diseases like typhoid, cholera or giardiasis.

Todd Fessenden is director of operations at Eagle River Water and Sanitation District in Vail. Photo By: Matthew Staver

State drinking water standards are the same for all localities, but each system faces its own set of challenges. As a headwaters state, many of Colorado’s drinking water providers are fortunate to draw water upstream from almost all other users. “Colorado has great source water,” says Diane Johnson, communications and public affairs manager for the Eagle River Water and Sanitation District, headquartered in Vail. The Eagle River district derives its surface water from watersheds that feed the Eagle River and Gore Creek. But even high country watersheds like these may contain small amounts of impurities from human and natural sources.

The Eagle Mine is an abandoned mine in the EPA’s Superfund program—that cleans up hazardous waste sites—located about 10 miles upstream of the district’s water treatment facility in Avon. Although the remediation plan for the site includes its own wastewater treatment plant—which removes about 175 pounds of zinc daily—district technicians must still be vigilant for metals in the river downstream of the old mine.

The community of Las Animas, on the lower Arkansas River in the southeastern quarter of the state, takes its drinking water from wells that tap the river’s alluvial aquifer. Folks there have complained about the region’s hard water since cowboys first dug wells in the canyon lands south of town. In 1997, after an engineering study determined the best way to remove minerals from the water supply was to use reverse osmosis (RO), Las Animas built an RO water filtration plant. The technology is much the same as that of a desalination plant: Pressurized water is pushed through a fine membrane, filtering out contaminants. In a desalination plant, the process yields a salty byproduct, brine. In Las Animas, the result is a “concentrate” of metals and salts that is sent to the city’s waste lagoon to settle before being processed in the wastewater plant.

The water tastes much better and doesn’t play havoc with visitors’ digestive systems, but the system was expensive and caused water rates to rise. Many residents could no longer afford to turn on outdoor spigots, leading to weeds replacing grass and gardens on almost every street.

The new technology had another drawback: “After RO, we began having problems with water main breaks,” says plant operator Roy Davis. “A good clean course of water” was at fault, resulting in the collapse of century-old pipes that had previously been supported by mineral deposits that formed on the pipes’ insides.

Not all water systems are able to make needed upgrades. For the South Swink Water District, which serves 610 customers in the Arkansas Valley from a 700-foot well, a radioactive contaminant, radium, presents problems that are seemingly insurmountable for an entity with so few customers and scant financial resources. To remove enough radium to meet EPA standards would be prohibitively expensive, according to Norman Noe, the district’s plant operator and secretary-treasurer. And once the radium is removed, there’s the problem of what to do with it.

The South Swink district is “under enforcement,” Noe says, meaning customers get a notice each month with their bills “more or less” telling them not to drink the water. The district and similar small rural districts are frequently privately owned, nonprofit entities, making them ineligible for grants open to larger water systems. “The CDPHE hasn’t pushed us to install treatment, but we have our backs to the wall,” says Noe.

The community’s best hope for a solution is the Arkansas Valley Conduit, Noe says. The pipeline, originally authorized 48 years ago by the Fryingpan-Arkansas Project Act, would bring water to 42 communities in the Arkansas Valley and could be completed in 10 years if all goes well.

The Eagle River district has its own problems— and solutions—that stem from its high country location. With few dischargers upstream, the Eagle River district’s raw water is of high quality, says director of operations Todd Fessenden. However, during spring runoff, the river carries water that is difficult to treat because it contains a heavier dose of organic materials. Its low temperature also makes it resistant to traveling through filtration membranes, because water gets more viscous as it gets colder. Because the district is consolidated from many predecessor entities, it has, in addition to a variety of water rights, three sets of drinking and wastewater treatment plants, plus 18 groundwater wells. So, during the spring runoff, the district chooses to draw water from its wells instead. The groundwater can be cheaper to treat than surface water because it is “essentially already filtered,” Fessenden says. Additionally, demand for water in the district is low during the runoff in late spring, making reliance on the wells easier.

Beyond that, the unique setup of three back-to-back-to-back sets of water and wastewater treatment plants permits the district, whose service area runs roughly from Vail to Cordillera—30 miles downriver— to do things other entities can’t. If the river is running low, the district can optimize its operations to enhance streamflows by pumping finished drinking water up-valley so it can be used, treated at an upstream wastewater treatment plant, and returned to the river as outflow upstream of where it was originally taken out.

Reuse Systems

As the state’s population grows—and it’s expected to nearly double by 2050—utilities are innovating in other ways. Recycling has become a major concern for water providers seeking to reduce the need for new water sources.

One method for using water to the last drop is a “purple pipe” system. Purple pipes denote a water system that provides nonpotable water. Denver Water’s recycled water system, which is about halfway to build-out, is the state’s largest. The system’s recycling plant takes effluent from a Metro Wastewater Reclamation District treatment facility and gives it additional treatment before it is pumped through 18 miles of purple pipe to customers, including Xcel Energy, the Denver Zoo, city parks and golf courses. Once the system is complete, it will offset enough

drinking water to serve almost 45,000 homes—and save the unneeded cost of bringing water destined for irrigation or industrial use up to drinking water standards.

The state has other purple pipe systems of note: In Colorado Springs, 26 miles of pipe carry nonpotable water—in this case, a combination of raw water and treated wastewater plant effluent—for industrial uses and irrigation. The Colorado Springs system was one of the first reclaimed water systems built in the western United States. In Boulder County, Superior’s reuse system features a combination of treated wastewater and raw water to irrigate 390 acres, including all commercial and multi-family landscaping in the town, as well as parks, medians and some open space, according to Superior Utilities superintendent Dmitry Tepo.

Northeast of Denver, a different type of project “recaptures” water to be turned into drinking water. Aurora Water’s Prairie Waters project retrieves wastewater effluent that has been treated and discharged into the South Platte River. Near Brighton, an amount of water equal to Aurora’s wastewater discharge is pumped from riverbank wells, piped to a man-made basin where it percolates through sand and gravel much as it would in a natural aquifer, and pumped back to Aurora to undergo state-of-the-art purification. The project increases Aurora’s water supply by 20 percent—about 3.3 billion gallons of water each year.

Prairie Waters wouldn’t be possible if Aurora didn’t import much of its source water from other basins, most notably the Colorado River, but also the Arkansas. If all its water were native to Aurora’s watershed, the city could only legally use it one time before sending it downstream to other water rights holders. Having purchased water rights from other basins, Aurora is allowed to use 95 percent of its water “to extinction.”

“In a perfect system, you could get almost 2 gallons per every gallon. Now we get 1.6 gallons per every gallon,” says Greg Baker, Aurora Water’s manager of public relations.

The cost of treating water can vary dramatically, depending on the system. Denver, which relies on mountain watersheds, pays about 18 cents per 1,000 gallons to treat water, while Las Animas, with its RO system, has costs of between 80 cents and $1 per 1,000 gallons for treatment.

In Aurora, Baker says the cost of drinking water is too variable and his department doesn’t have a number for it. “[In] wet years like 2009, our treatment costs were low, since we didn’t have to use as many chemicals and pump as much water around our system,” he says. “Fast forward to 2012 and our costs will be much higher. Higher use of Prairie Water exacerbates this—it’s a more energy-intensive system than is our mountain water system.”

Wastewater Treatment

If the thought of drinking water from a source that is downstream from another system’s wastewater effluent bothers you, consider this: There is no new water in the world. The Earth got its one and only delivery of water 4.4 billion years ago. There is disagreement about how that came to be, but no water is being created or destroyed, only recycled through the eons. Your next glass of water may contain molecules of water that were in the pee of a Columbian mammoth that roamed the Front Range during the Pleistocene Era.

Fortunately, Colorado’s public wastewater systems, which collect wastewater from homes and industries, provide an effective layer of treatment between dirty water and the stream—and downstream water users.

These systems also owe their genesis to heightened environmental awareness in the late 1960s and 1970s. Passed in 1972, the Clean Water Act was established to eliminate releases of high amounts of toxic substances into rivers and lakes and ensure that water would meet standards necessary for human recreation as well as aquatic life. Wastewater systems must receive a permit—granted by CDPHE following EPA rules—to build and operate plants.

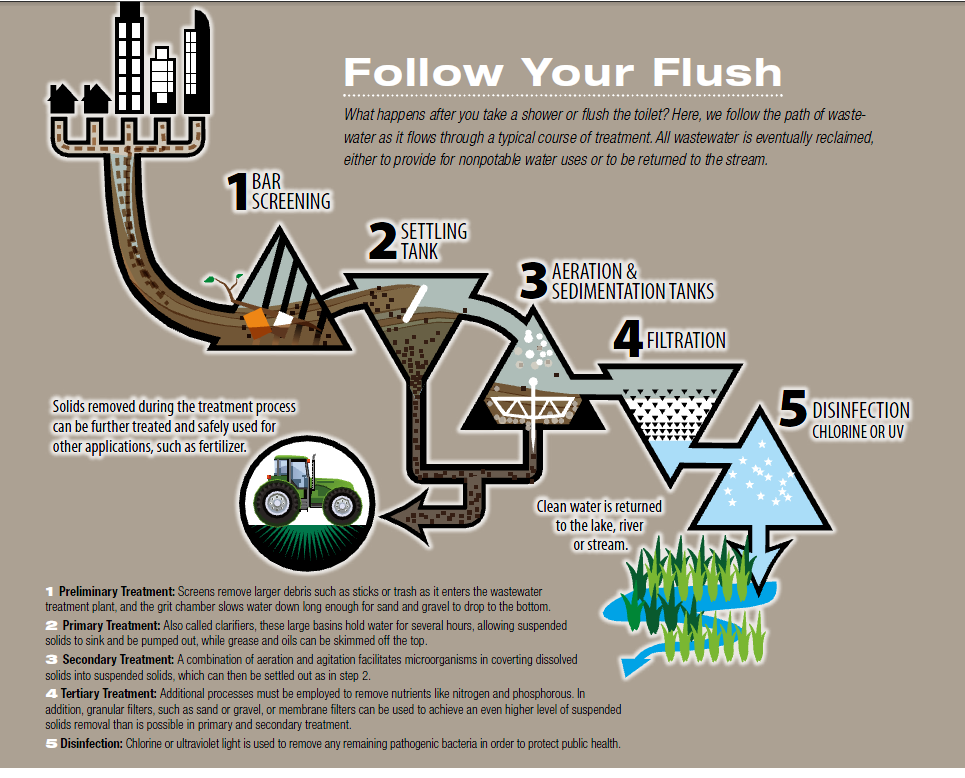

A wastewater plant has a variety of tanks of different shapes and sizes, as well as rectangular aeration basins. Solid waste is separated from the water and becomes treated biosolids, suitable for use in landscaping and agriculture. A combination of aeration, gunkeating microorganisms, gravity and a variety of chemicals is used to cleanse the wastewater so it is safe to return to a waterway.

Wastewater treatment standards for some contaminants can be harder to achieve than drinking water standards because they take into account the uses of a waterway where outflow is discharged. The bar is set high for Eagle River’s wastewater plants because of the aquatic life in the river—it turns out fish are more sensitive to some contaminants than humans. Across the state, localized standards for discharges are set in consideration of downstream recreational, agricultural or environmental uses.

Back at the J.D. Phillips plant in Colorado Springs, UV light replaces the addition of the disinfectant chlorine for a final cleansing. The UV system, rare for a wastewater plant, “just uses light, so there are no chemical byproducts,” plant superintendent Hoyt says. “[The UV light] alters the DNA of the bugs so they can’t reproduce,” he explains. “What makes people sick isn’t the bacteria in the water, but the growth of bacteria later.”

What really makes the plant unusual, Hoyt says, is its use of recycled whey to add carbon to the treatment process. Because the plant largely processes wastewater from homes rather than industry, it took in too little of the carbon needed to feed the “bugs”— a water-treatment professional’s term for pathogen-munching microorganisms—that do the work of removing nitrates in one of the plant’s cleansing processes. Additional chemical inputs had to be purchased to compensate for the lower carbon levels until a local dairy approached the utility to determine how it could reduce its cost for discharging whey, a byproduct of making cottage cheese, into the wastewater stream.

Industries are often required to pretreat wastewater to remove contaminants specific to their processes before putting it into a utility’s collection pipes. Whey, it turns out, is a good source of carbon. Soon, the plant was taking delivery of whey from the dairy. “Here’s the innovative part,” Hoyt says. “We discovered fermented whey works even better.” Whey had been left in a tank long enough to ferment, and when it was used, its heightened powers were noticed. Total savings on reduced chemical inputs in the first year of whey usage: $80,000.

Other wastewater systems have also found ways to achieve savings. Metro Wastewater Reclamation District, which serves about 1.7 million people in a service area that includes Denver, Arvada, Aurora, Brighton, Lakewood, Thornton, and Westminster, uses methane produced during biosolids treatment to fuel its plant, freeing up enough electricity to power almost 5,000 homes. The potential here is significant: Three percent of electricity generated in the United States is currently used to power water treatment facilities. According to Barbara Biggs, Metro’s governmental affairs officer, the single largest demand for energy in wastewater treatment comes from the blowers that force air into the secondary treatment process.

The Southeast Metro Stormwater Authority used a unique drop structure to prevent the banks of Cottonwood Creek in Arapahoe County from eroding after storm events. Excessive bank erosion can negatively impact riparian vegetation and aquatic life as well as nearby human activities. Stormwater management also aims to minimize pollutants in runoff entering streams from adjacent land surfaces. Photo By: Josh Duncan

Stormwater Regulation

The third segment of the public water system triad, stormwater, had to wait until the late 1980s for a federal makeover. Research during the late 1970s and 1980s indicated that stormwater runoff from industrial sources, municipal storm drains and construction sites significantly degraded water quality. Passed in 1987, the Water Quality Act requires industrial plants, municipal separate storm sewer systems—often called “MS4s”—and construction sites to obtain permits to discharge stormwater.

In EPA parlance, those discharges come from “point sources”—specific outlets such as pipes, ditches and concentrated animal feeding operations.

Stormwater pollution also comes from “nonpoint sources,” including excess fertilizers on lawns, motor oil and other toxic chemicals lingering on paved surfaces, and bacteria and nutrients from livestock and pet wastes. Nonpoint-source pollution is carried by rainfall or snowmelt moving

over and through the ground. As the runoff moves, it picks up natural and man-made pollutants that then flow into waterways.

Urbanization has exacerbated the issue because runoff moves at a faster rate over impermeable surfaces, such as parking lots, and can’t be absorbed by the soil for return to waterways as groundwater recharge. Fast-moving water from storm events can also cause waterways’ banks to erode. Several measures are used to slow the water’s unseemly rush to rivers and lakes, including retention basins and wetlands, as well as screens to block trash. If you’ve ever been to a big-box store with an improbable pond in a corner of the parking lot, it is probably a retention basin—likely dry most of the time, with a drain from the parking lot to channel stormwater. The basin allows water to be absorbed into the ground or evaporate.

In Colorado, as in most states, stormwater is managed but not treated before it is discharged into waterways. “People don’t realize that if they over-fertilize, don’t pick up dog doo-doo, it ends up in the river,” says Kristen Winn, Grand Junction’s public information coordinator and spokeswoman for the region’s 5-2-1 Drainage Authority, which handles stormwater for the entities of Grand Junction, Mesa County, Fruita, Palisade and the Grand Valley Drainage District.

Jeff Besse, stormwater specialist for the city of Colorado Springs, spends much of his time educating residents, education being one of the key directives given to MS4s by the EPA. Besse says the effort “focuses primarily on K-8 students, trying to get them to understand early on.” Beyond targeting behavioral change, Colorado Springs relies on citizens to help identify illicit discharges, Besse says. Potential sources of pollution include carpet cleaning services, spray washing, landscaping industries, and cooking grease from restaurants.

So what does the future of water treatment hold? What’s certain is that the technology of water purification won’t stand still and that standards and permitting processes will continue to evolve. As technology advances and our understanding of the impacts of chemical and biological agents on human and aquatic health grows, so do our expectations. As Aurora Water’s Baker reminds us, “Agencies are now concerned about contaminants measured in parts per trillion.”

Although the EPA has a list of 90 contaminants that must be controlled, it is required to periodically post a Contaminant Candidate List and then determine whether five or more of the candidates should be regulated. The agency is now calling for nominations for its fourth list, and there should be no dearth of candidates.

As advanced as our regulations and water treatment capabilities have become, there remains a personal level of responsibility in keeping contaminants out of streams and water supplies. “Prescription medication, ingredients in personal care products, some of that stuff we are never going to be able to take out. Triclosan used in antibacterial hand soap, for example, is incredibly resistant to treatment and unnecessary,” says Biggs. “Residents need to be aware.” Whether it’s picking up after a pet to prevent stormwater pollution, locating the dishwasher detergent on the shelf that doesn’t contain phosphorous, disposing of medications properly, or buying the hand soap sans triclosan, we all have a role to play in keeping our water clean.

Print

Print